DURING PRODUCTION INSPECTION

WHAT IS DURING PRODUCTION INSPECTION

Check on the key characteristics of products during their production. In general, this inspection takes place when approximately 40-60% of total order quantity is produced. Depending on the product and the manufacturing process, the dpi may cover raw materials, partially completed products, and/or finished products and their packaging. Also the most important production status is verified at this stage.

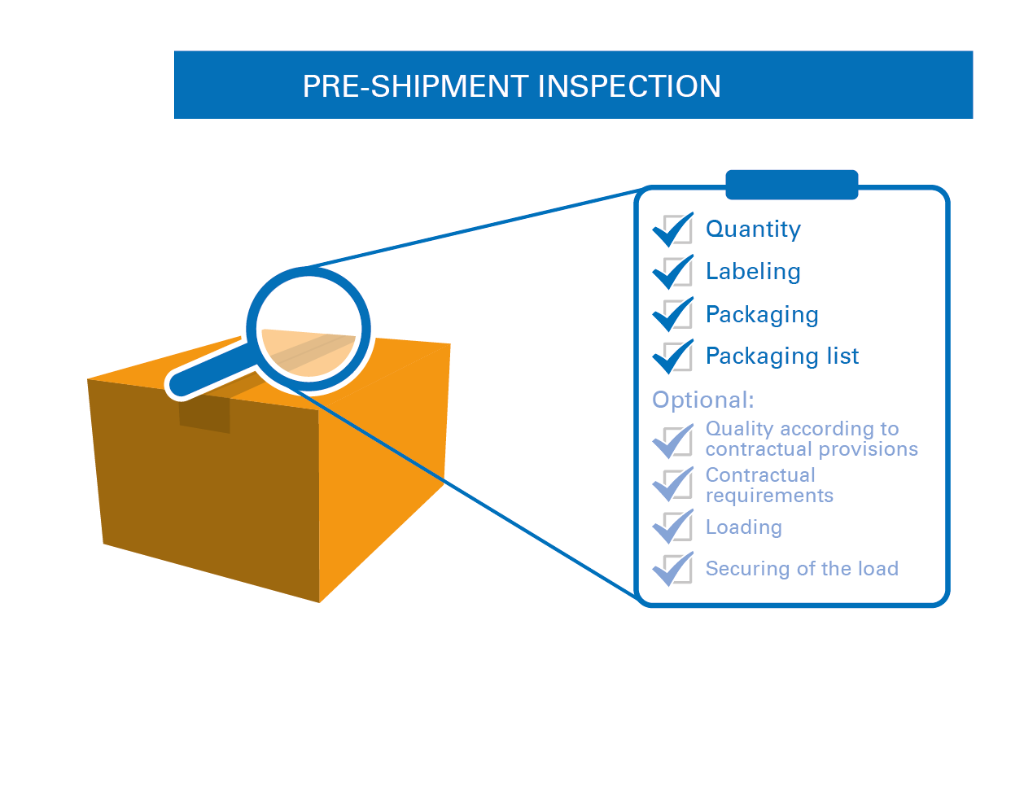

PRE-SHIPMENT INSPECTION

WHAT IS PRE-SHIPMENT INSPECTION

Pre-shipment inspections (PSI) – Ensure that finished goods conform to your specifications. (Carried out when production is finished and at least 80% are packed into cartons.) Each product is different and has wide variety of defects that can occur. Our inspections are performed using specific criteria based on each product’s style, function, specifications and other important information.

FINAL RANDOM INSPECTION

We offer reliable Final Random Inspection Services that come into play once the merchandise is completely packed and ready. We employ a team of inspectors that conducts final inspection based on random selection of products making sure to include all styles, colors, sizes, assortments, markings etc. while checking the Quantity, Quality, Workmanship and Functioning of product. Further they ensure that the various parameters of color, size and other specifications and packaging, etc., is matching to stated specifications.

Standards Used For Inspection

AQL- MIL-STD 105 D/ABC-STD 105/DIN 40080/BS 6001.For inspection of piece goods (Garments/Home Furnishing/Hard Goods) 1.0, 2.5.4.0 etc.